Pedrini installs a complete Tech12 plant for the production of thin slabs at Welt Graniti

Welt Graniti, a leading company of the Verona industrial area specialising in the cutting and processing of granite blocks, has been focused in recent years on the search for solutions to expand the use of natural stone.

Pedrini, Welt’s technological partner for years, has been able to realize this ambitious goal by designing a complete Tech12 plant for the industrial production of 12 mm-thick slabs: a thinner and lighter product that further opens up the stone business to new and different application opportunities.

The Pedrini plant includes the entire working process, from the blocks cutting to the production of trimmed, calibrated and polished 12 mm-thick slabs, which consists of the following innovations:

- Multiwire machine Jupiter GS220-F108-TS to cut blocks into slabs. It is the first machine with 108 diamond wires with 5,3 mm diameter that cuts an entire block into 107 slabs with a 12 mm thickness at once.

- Loading and unloading robot MANTIS B419 to automatically load and unload slabs with ground level translation and with the possibility of match book processing system.

- Cross-cutting/trimming machine B715AR to square material on all the 4 sides with perfect angles, equipped with slab reading sensors that allows the automatic processing.

- Planetary calibrating machine SPECTRA B220ES to grind the slabs thickness in a homogeneous way. The machine is equipped with two calibrating groups, each one composed of the exclusive Grifone rotating head that works on the entire slab surface ensuring planarity and regularity of the final thickness.

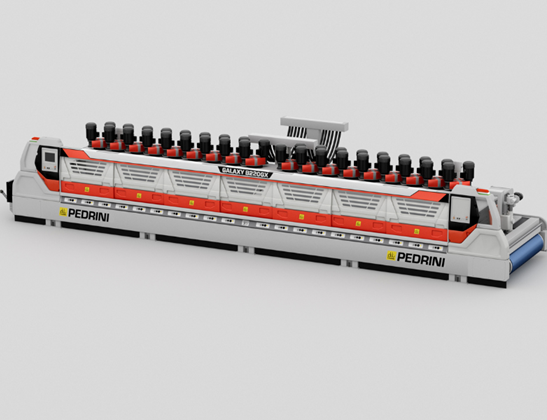

- Polishing machine GALAXY B220 to achieve high level of slab polishing thanks to the Aquila honing heads and to the 20 Antishock polishing heads with 7 abrasives mounted on the patented Rotor spindles with pneumatic counterpressure functioning as standard. Rotor spindles ensure a perfect balance of the beam movement and the abrasives consumption control. Moreover, GALAXY is equipped with the innovative Smart Touch electronic pressure management that allows to differentiate the workload on different areas of the slab.

- Automatic polyethylene sheet dispenser B417 to apply protective film over the slabs surface to secure it during the storage and transport phases.

“We supported Welt Graniti in this evolution because we are convinced that the future is the large, light, performing and versatile slab. Tech12 is a high-tech project that goes well with the concepts of ecological transition that are being talked about a lot in this period”. – stated Giambattista Pedrini, CEO of Pedrini S.p.A.

Indeed, producing 12 mm-thick slabs has multiple benefits: from the industrial point of view, both the blocks yield – equal to 53,7 m²/m³ – and the production capacity considerably increase. From the sustainability point of view, the thin slab allows to reduce the environmental impact during the different processing steps thanks to an optimized block management which avoids waste, reduces excesses deriving from the cutting operations and decreases water and energy consumptions.

Related news

Thank you for your message.

Error

Do you need more info?

Feel free to contact us for product information, events, customer care and open jobs.