How does granite cutting work?

Granite is one of the most valued materials by interior design professionals, thanks to its natural beauty and durability. However, this material also presents challenges that should not be underestimated during processing. In this article, we'll explore how granite cutting works, the difficulties it entails, and how Pedrini's innovation can make this process precise and efficient.

In this article, we'll cover:

The challenges of granite cutting

Granite is one of the most revered materials in the natural stone industry, known for its toughness, variety of colors, and unique textures.

In particular, the hardness of granite, while a sought-after quality for applications requiring durable and resilient materials, poses the main challenge in its cutting process. Additionally, the variability of its structure, with veins varying from one block to another, necessitates a highly personalized and flexible approach during cutting to adapt to the specificities of each individual block.

To overcome these challenges and proceed with granite cutting safely and efficiently, it is essential to rely on advanced technologies and high-precision machinery.

Multiwire machines enable clean and precise cuts, preserving the integrity of the material and ensuring slabs of uniform thickness.

Moreover, the use of these advanced tools not only improves the efficiency of the cutting process but also helps minimize material wastage, contributing to a more sustainable production.

Rely on Pedrini's expertise for impeccable granite cutting.

Contact us

How granite cutting works

To cut granite blocks precisely and uniformly, it's essential to rely on the advanced capabilities of multiwire machines.

These machines perform block cutting using a series of diamond wires for the industrial production of granite slabs in various sizes. With multiwire machines, it's possible to simultaneously produce slabs of different thicknesses.

The process begins with the accurate positioning of the granite block on the machine's block-carrying trolley. At this point, following the detailed project specifications, including the cutting speed and start and end cutting settings, the computerized control system takes command, guiding the machine in the cutting process. This precision technology ensures that each cut is made with millimeter accuracy, guaranteeing high-quality results without material wastage.

Thanks to the high technological level of these machines, granite cutting has become a highly efficient process that maintains the integrity and natural beauty of the material, meeting the growing demands of the market.

Pedrini's solutions

Pedrini stands out in the natural stone cutting sector for its highly innovative solutions. Indeed, our machinery is designed to address the complexities of granite cutting, combining precision, efficiency, and material integrity.

Here are some of our key solutions:

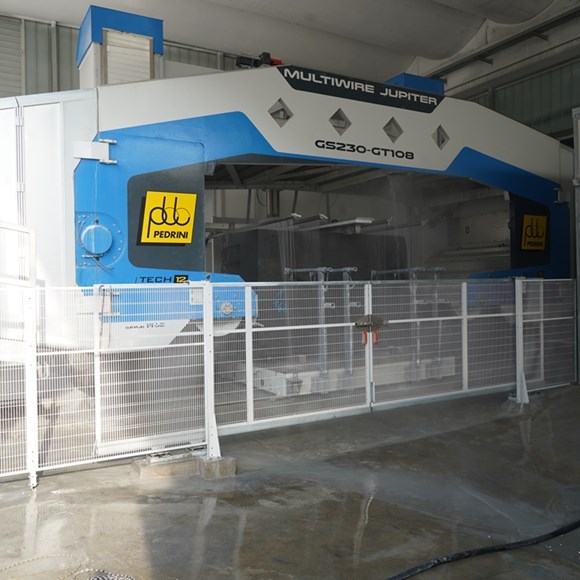

Multiwire Jupiter GS230: this specific model for granite cutting utilizes a series of diamond wires to cut blocks efficiently and precisely. Available in various models differing in the number and diameter of wires, this machine can produce slabs ranging in thickness from 2 to 10 cm directly from the same block. Thanks to the hydraulic tensioning system and wire configuration, it ensures uniform cuts and maximum production flexibility. It also features an intuitive graphical interface and automated cutting cycles

Multiwire Jupiter GS230 TECH12: this machine is designed for the industrial production of granite slabs with a thickness of 12 mm, performing rapid block cutting with a series of diamond wires with a diameter of 5.3 mm. It is available in different models varying in the number of wires: 48, 60, 72, and 108. Multiwire Jupiter TECH12 is part of a project started by Pedrini in 2019 to industrialize the production of 12mm-thick slabs, starting from the cutting of natural stone blocks, including granites, quartzites, and marbles, to achieve a more versatile and lightweight end product.

Pedrini's technologies, thanks to their advanced engineering level, allow overcoming the challenges related to the hardness and variability of granite, enabling the production of superior quality slabs ready to be used in a wide range of applications.

Relying on Pedrini means choosing experience, innovation, and quality after-sales service, essential for those working in the granite processing sector.

Discover more about our solutions for granite cutting!

Granite cutting

Related news

Thank you for your message.

Error

Do you need more info?

Feel free to contact us for product information, events, customer care and open jobs.