How does marble resining work? Technologies and solutions

Marble resin application is a key process in the stone industry, essential to ensure the quality and durability of the finished product. This technique, which enhances both the aesthetics and resistance of the stone, has become indispensable in the modern marble industry. In this context, Pedrini stands out as a leader in the production of machines for marble resining, offering innovative technologies and efficient solutions.

In this article, we will explore:

- Meaning and importance of marble resining

- How marble resining works

- Pedrini's solutions for marble resining

Meaning and importance of marble resining

Marble resining represents a fundamental technological step in the world of natural stone processing. This process not only heals and restores slabs even in-depth but also significantly improves the technical characteristics of the treated materials, such as resistance and durability. Additionally, resin application plays a crucial role in enhancing the aesthetic value of marble.

The treatment involves the use of epoxy resins, chosen for their exceptional and long-lasting adhesive properties. These resins are carefully mixed according to specific proportions before application, ensuring an optimal result.

Resin application is particularly important for more fragile materials, where vulnerability to breakage and damage can be significant. In these cases, a reinforcement net is applied to the back of the slab, fixed with epoxy resin, thereby increasing the structural strength of the material.

How marble resining works

The process of marble resining is a meticulous and detailed operation, carried out through five distinct phases, each crucial to ensuring the best result:

- Material loading: first and foremost, the slab is accurately positioned on mobile supports designed to facilitate handling and transport of the slab through the various phases of the process.

- Drying and preheating: subsequently, the slab is carefully dried and preheated.

- Application of epoxy resin: the central phase involves the uniform application of epoxy resin on the surface of the slab.

- Catalysis and hardening: the applied resin undergoes a catalysis and hardening process, which can take place in a microwave oven and/or in a multi-level tower, depending on specific requirements. This step is crucial to ensure that the resin hardens correctly, improving the resistance and durability of the marble. For this important step, Pedrini employs the exclusive Microwave B460, a microwave oven capable of efficiently and completely safely carrying out the catalysis phase, thanks to its closed-door structure.

- Material Unloading: finally, the treated material is unloaded, ready for the subsequent processing stages.

Do you want to learn more about how the marble resining process works? Pedrini explains it to you!

Contact us

Pedrini's solutions for marble resin treatment

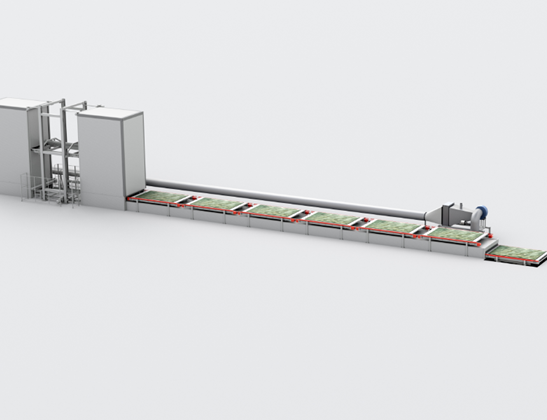

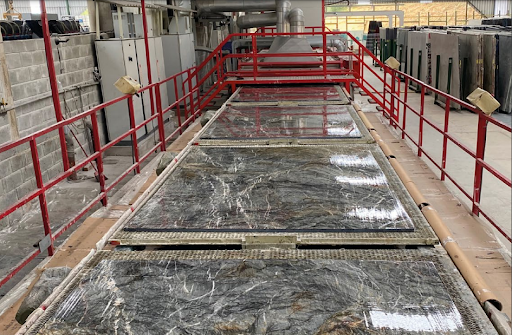

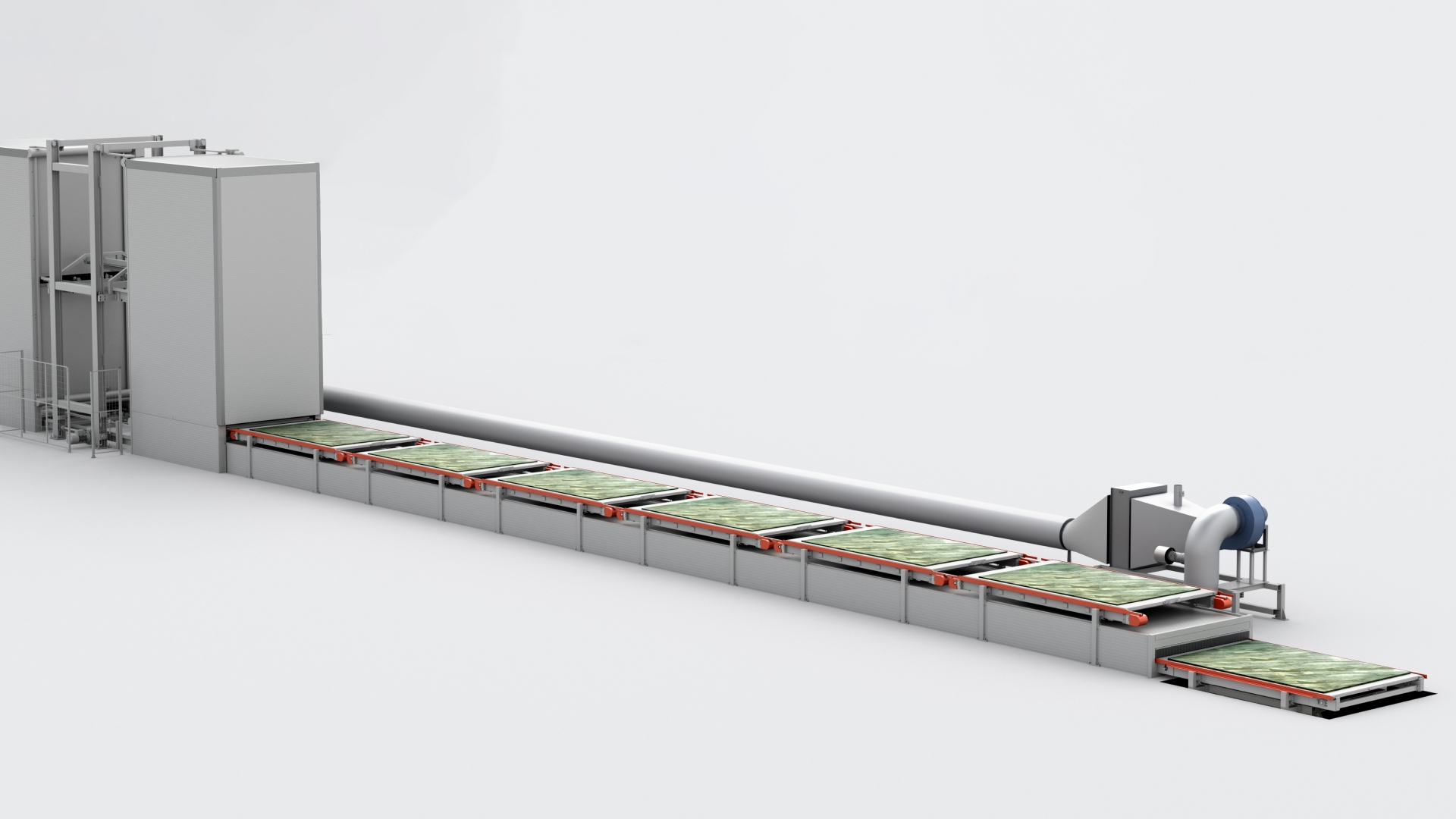

Pedrini, a leading company in the production of machinery for natural stone processing, provides cutting-edge solutions for marble resin treatment, such as the advanced Resinline system, ensuring efficiency and consistent production.

Customizable based on the product, type of resin, automation level, and available space, Resinline systems can achieve production speeds ranging from 6 to 60 cycles per hour.

Pedrini offers exclusive products to customize the resin treatment line:

The drying tunnel performs a dual function by eliminating residual moisture from the slabs and heating them to the appropriate temperature for resin treatment, approximately 40°C.

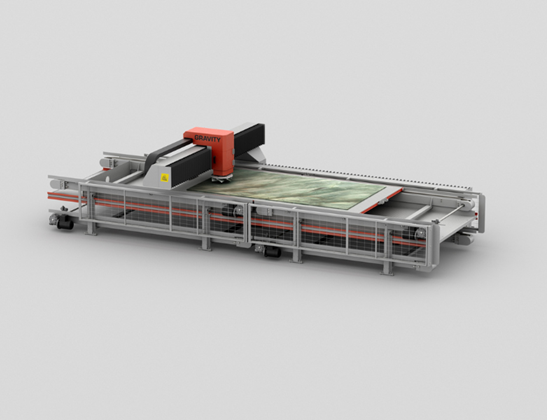

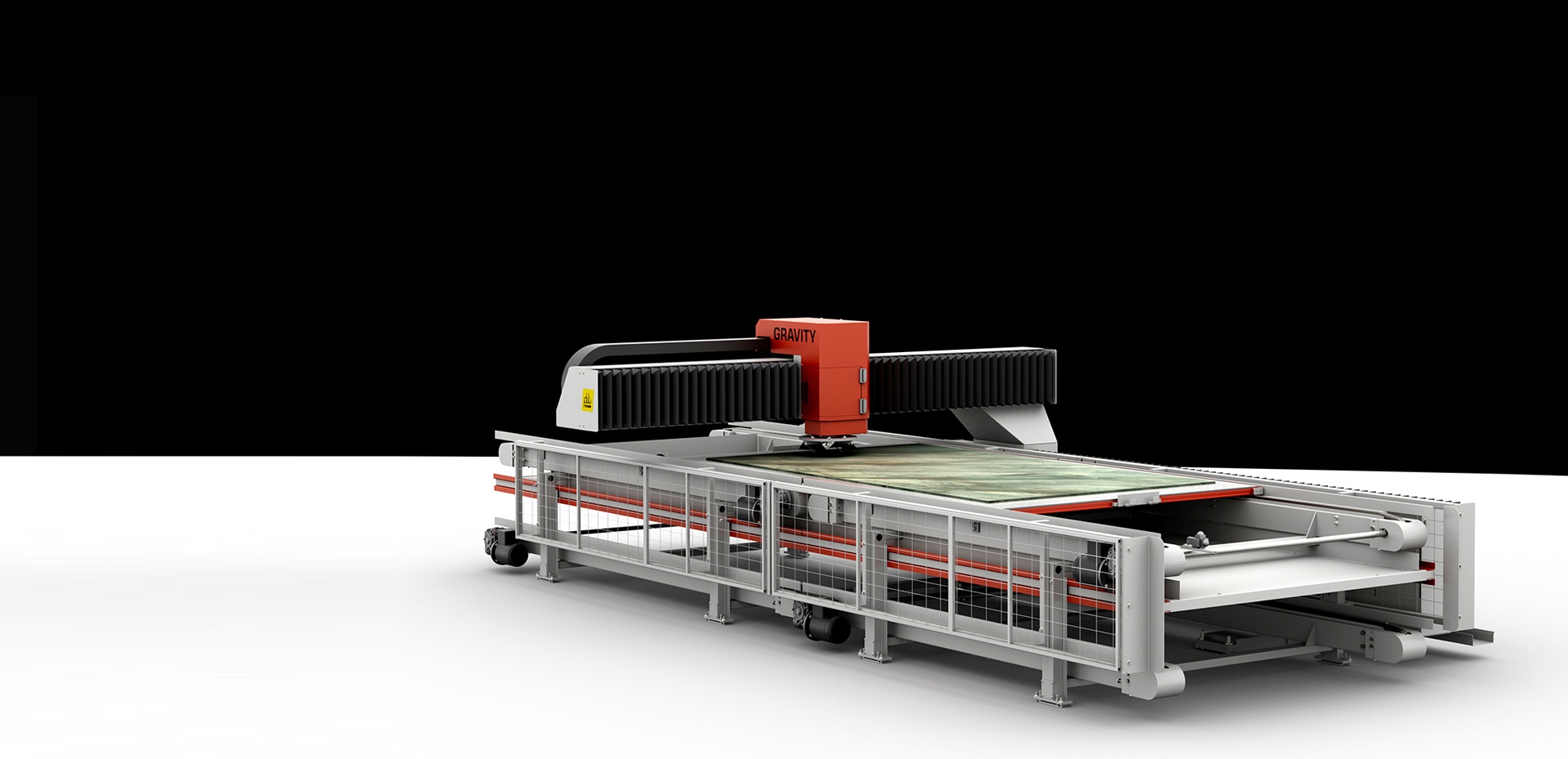

To simplify the operator's work during resin mixing and application, Pedrini also offers various advanced solutions, including the automatic resin mixer, which can be connected to the Gravity B480. This Cartesian robot is designed to manage the resin application cycle automatically, acquiring the dimensions and shape of the slab, processing the tool path, and distributing the resin precisely.

All working parameters are easily programmable through a touch-screen panel, and with its versatility in using different tools, the Gravity B480 represents a technologically advanced and highly functional solution for the marble industry.

Finally, the use of the microwave oven in the resin treatment line offers several advantages, such as:

- Reduction of resin viscosity

- Uniform activation

- Reduction of catalysis times and improvement in polishing

Moreover, this technology simplifies the touch-up phase, reduces energy consumption, and the space required for material storage, ensuring safety for operators and compatibility with various types of marbles and granites.

Want to learn more about Pedrini solutions for marble resin application? Discover all our dedicated products!

Resining

Related machines

Related news

Thank you for your message.

Error

Do you need more info?

Feel free to contact us for product information, events, customer care and open jobs.